Industrial Wet Drum Magnetic Separator Application

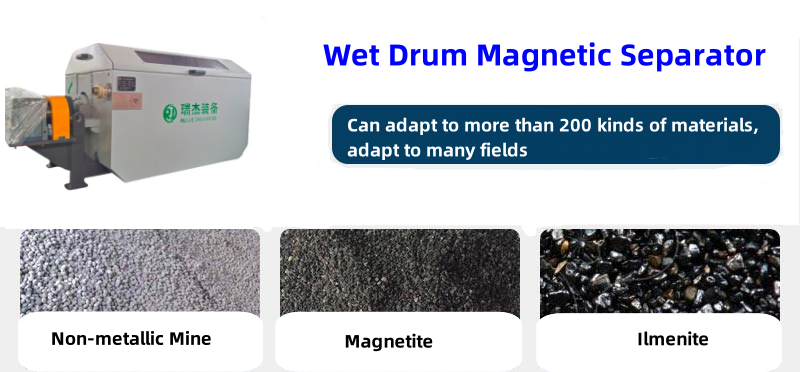

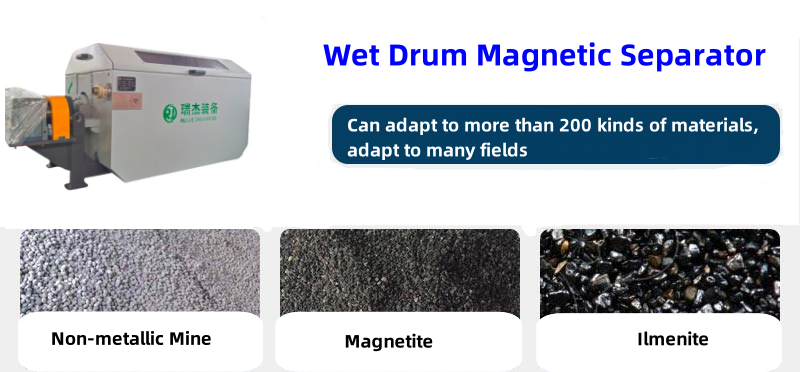

The magnetic separator should be used for iron removal in various industries such as weak magnetic ore, iron ore, limonite, quartz sand, potassium feldspar, hematite, garnet, mine, magnetite, tailings, weak magnetic ore, sulfuric acid slag, abrasives, refractory materials, building materials, etc., and some iron removal equipment can also be used for multiple purposes.

The super magnetic separator wet magnetic separator can be transformed according to the needs of customers, and the equipment can be customized according to the site conditions to meet the needs of the majority of users.

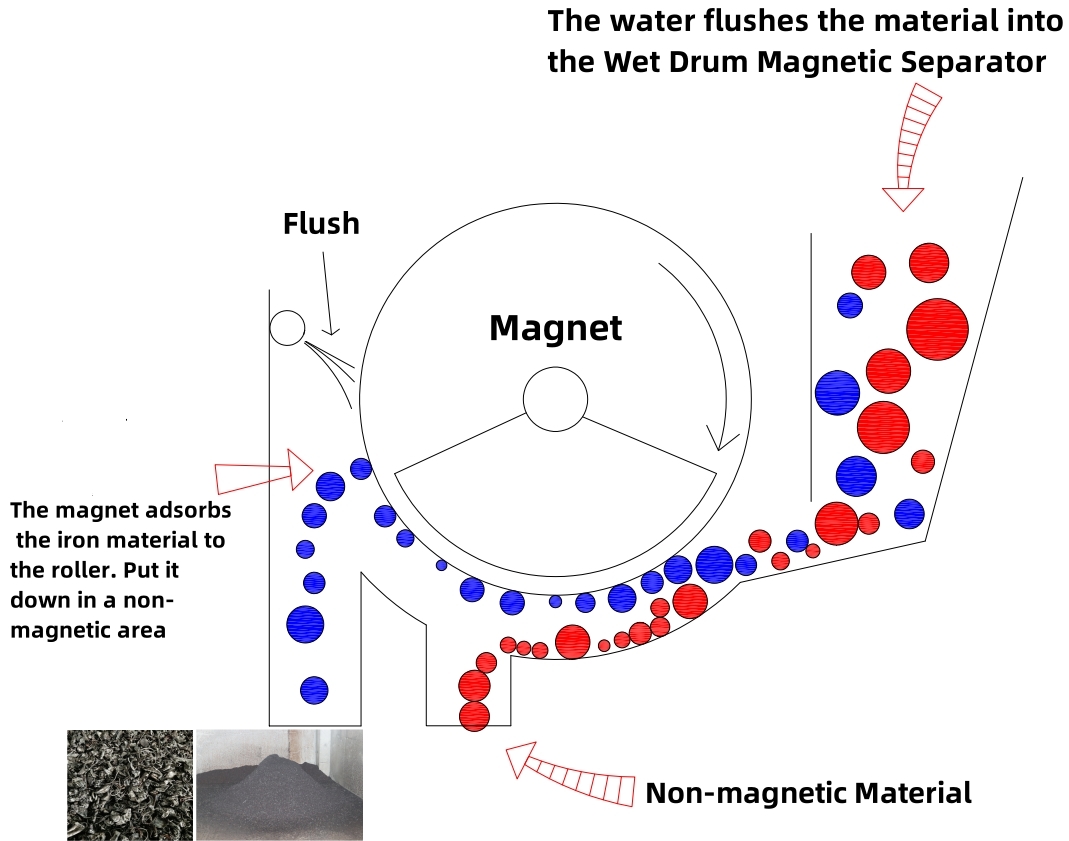

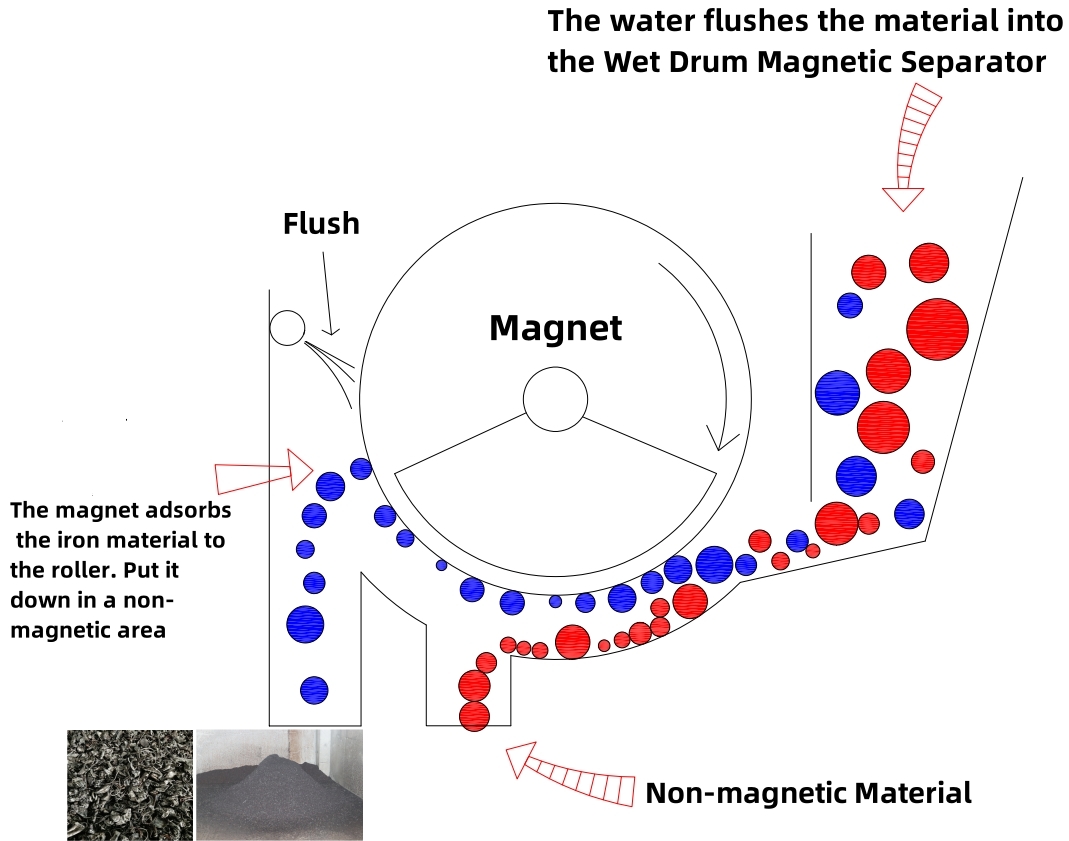

Drum Type Wet Magnetic Separator Principle

When the material is mixed with water and enters the working area of the magnetic drum, the magnetic particles are adsorbed on the surface of the strong magnetic drum, forming a magnetic chain, which is transported to the fine material outlet by a continuously operating drum. Magnetic particles are removed by the high-pressure injection of the ore flushing pipe to realize the separation of magnetic particles.

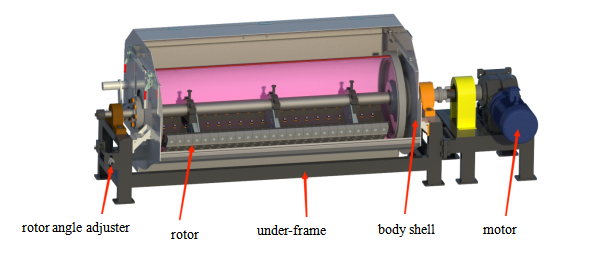

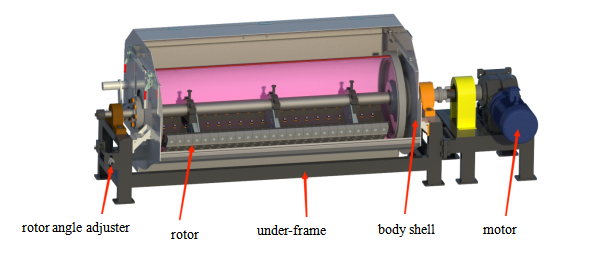

The wet drum magnetic separator adopts the principle of magnetic blocks to absorb iron materials for separation. It is generally composed of top cover, body shell, flushing water pipe, magnetic drum, motor, etc. It has the characteristics of simple structure, large processing capacity, high magnetic separation rate, and long service life.

Automated Wet Drum Magnetic Sorting Machine Features

●Low demagnetization rate and high magnetic separation accuracy; The angle can be adjusted according to actual conditions.

●The drum has a large thickness and is made of stainless steel material, which is wear-resistant and practical. Open magnetic system design, with a 150 degree magnetic wide angle, produces high grade minerals and minimal tailings residue.

●Large processing capacity and high magnetic separation rate.

●Stable operation, low failure rate, and long service life.

●Simple & compact in structure, easy to install, and easy to integrate into existing systems.

Magnetic Drum Separators Structure

Magnetic Drum Separators Equipment Technical Parameter

Model | Dimensions (L*W*H)(mm) | Drum Length(mm) | Processing Capacity(t/h) | Weight(kg) |

CTS-50090L | 1933x1014x913.5 | 900 | 8~15 | 862 |

CTS-50120L | 2233x1014x913.5 | 1200 | 10~20 | 999 |

CTS-50150L | 2600x1014x913.5 | 1500 | 13~25 | 1200 |

Wet Magnetic Separator Field Use Video

Ruijie uses the best rare earth magnetic material (NdFeB) in China and designs the structure. Prevents wear and tear through wear-resistant aluminum or stainless steel housings, end flanges, long working hours and lubricated bearings.

The following is one of our customer's incineration Bottom ash (IBA) sorting plants, where the machine is mainly used to screen iron absorption materials with an extremely high iron removal rate of 99%

Non-demagnetization Reliable Durable Wet Drum Magnetic Separator Application Area

Our wet magnetic separators are used in a wide range of fields.Industrial Wet Drum Magnetic Separator is widely used in mining, metallurgy, building materials and other fields, and is favored for its high efficiency, energy saving and environmental protection.

Iron Material Separated By the Automated Wet Drum Magnetic Separator

The following are the iron materials that we have obtained from the incineration ash (IBA) by wet separation, which can reach 100% purity.