Application

The jig machine is a high-efficiency energy-saving gravity separation equipment developed on the basis of the traditional sine wave jig machine. The difference from traditional sine wave jig machine is that: the flow fluctuation curve of jig machine is sawtooth wave, its rising water flow is fast and the falling water flow is slow. The bed rises and loosens under the action of the rising water flow, and then settles slowly. The effective action time is long, which can greatly save the make-up water under the screen and greatly reduce the lower limit of particle size recovery. Compared with the sine wave jig machine, its operational recovery rate has increased by Sn: 3.01%, W: 5.5% and water consumption has decreased by 30-40%.

Principle

The jig separator works based on specific gravity differences between ore and gangue. When the mineral mixture, which contains minerals of different specific gravities, is fed into the jigging chamber filled with water, the pulsating water flow causes the particles to move and interact with the water.Heavier minerals with a higher specific gravity tend to sink to the bottom of the jig sorting tank, because they are less affected by the upward - moving water flow. Lighter minerals or gangue with a lower specific gravity are more easily lifted and carried by the water flow, remaining in the upper part of the jig separator sorting tank. Then, different minerals can be precisely separated.

Feature

● With compact structure, small in size, and large processing capacity per unit area.

● Jig frequency is 50~90c/min, easy for adjustment, installation and maintainence.

● The use of cam mechanism transmission effectively improves the recovery rate of fine grained useful minerals, and has excellent beneficiation effect on fine-grained materials.

● The pulsating water flow profile of a sawtooth-wave jig exhibits a sawtooth waveform, characterized by a rapid upward surge and a gradual downward return, water saving and long continuous working time.

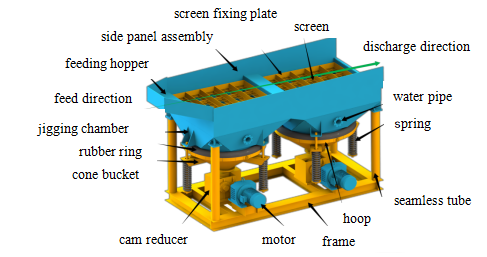

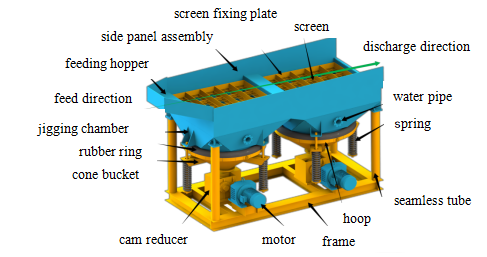

Structure

Technical Parameter

Model | Jigging Chamber | Feed Particle Size (mm) | Supply Water Under Screen ( ) ) | Supply Water Pressure Under Screen (Mpa) | Processing Capacity (t/h) | Power (kw) | Dimensions (L*W*H) (mm) | Weight (kg) |

Shape | Area ( ) ) |

JTY21 | Trapezia | 2.56 | <15 | 3~6 | ≥0.1 | 10~30 | 5.5 | 2230x1740x2600 | 2103 |

JTY42 | Trapezia | 4.5 | <15 | 20~50 | 5.5x2 | 4030x1980x2650 | 4200 |

JTY63 | Trapezia | 6.75 | <15 | 30~70 | 5.5X2,7.5X1 | 5560x1885x2620 | 5916 |

JTY82 | Trapezia | 8 | <15 | 40~80 | 11x2 | 5200x2050x3250 | 7205 |

)

)