The main components of slag produced by domestic waste incineration power generation include slag, glass, ceramics, stones, etc., most of which resemble porous and light gray sand grains.

Although slag is solid waste, it is a renewable resource that supports and strongly encourages development, as directed by the GB18485 "Pollution Control Standards for Domestic Waste Incineration".

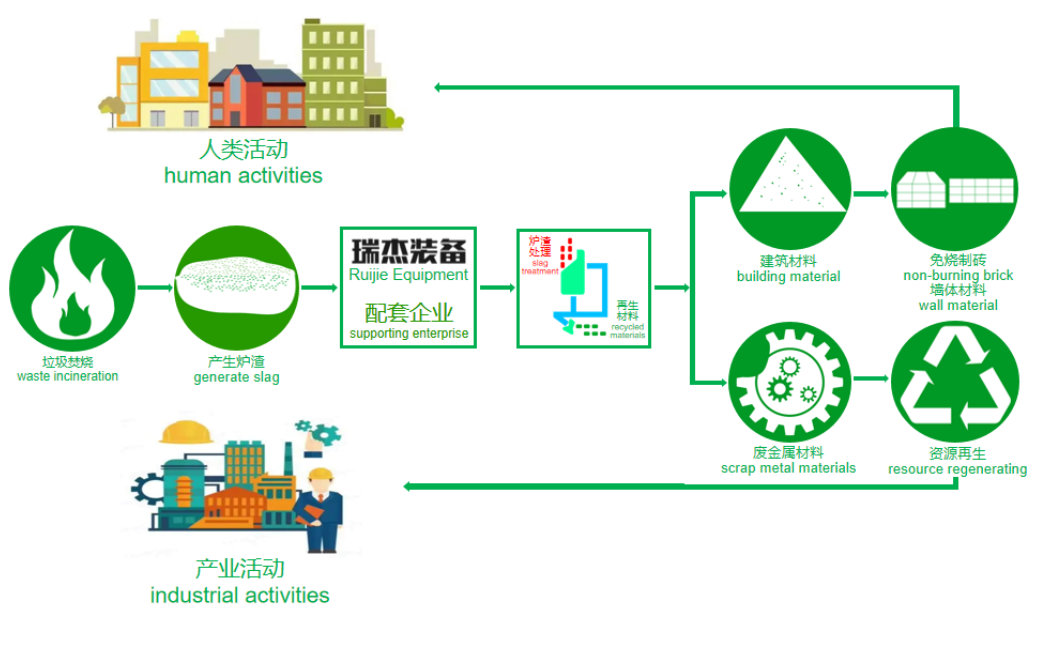

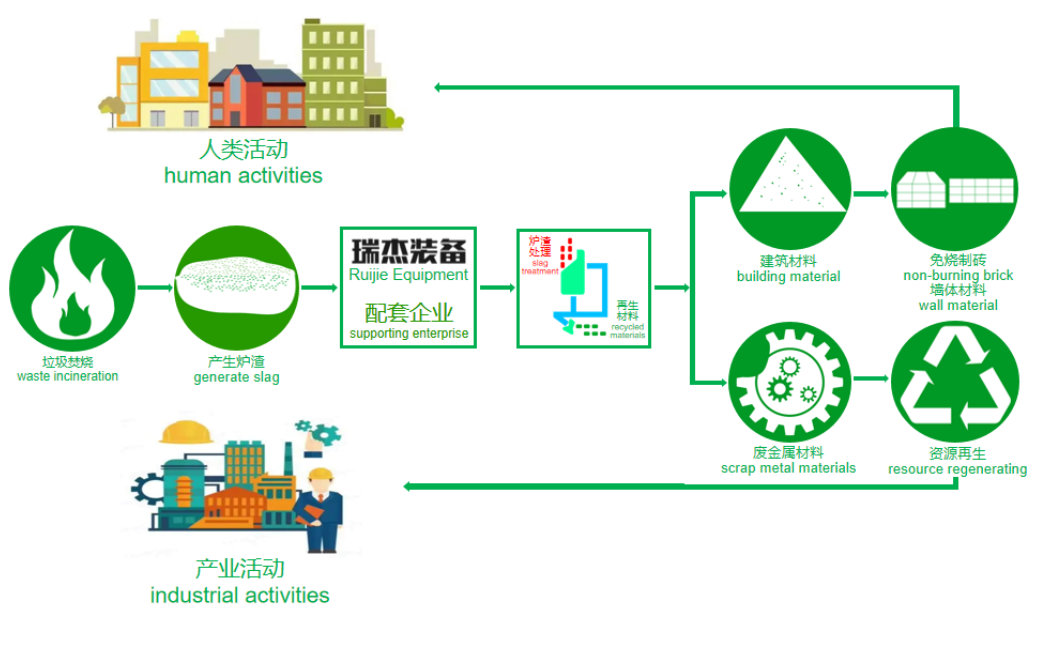

The new process of slag treatment creates new value for the use of resources

Slag treatment mainly uses the differences in the physical properties of ash and slag components to carry out screening, crushing, impurity removal, magnetic separation, non-ferrous metal separation, precious metal separation, tailings recovery, waste water treatment and other resource processes to achieve the recovery of iron, copper, zinc and other valuable metals. After sorting slag, recycled blocks are prepared, and the finished sand can be used for roadbed and bottom aggregate.

Process Flow:

Our company mainly reprocesses the slag from the waste incineration power plant by physical methods (including particle size screening, magnetic separation, buoyancy separation and eddy current separation), separates out iron, metal aluminum and a small amount of non-magnetic metals (metal copper, etc.), and construction sand (coarse, medium, and fine sand) can be obtained at the same time.

The sorted metal materials are sold to recycling units for reuse; Coarse, medium and fine sand materials are used in brick-making or reusing by building material production plants. The specific production process flow and pollution production process diagram are shown in the figure:

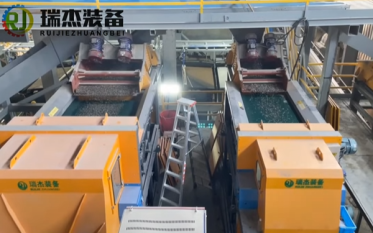

Feeding: Loading by forklift truck

Sieving: The trommel screen equipment is used to divide the slag into coarse slag and medium slag, which is convenient for the next step of circular magnetic separation and crushing.

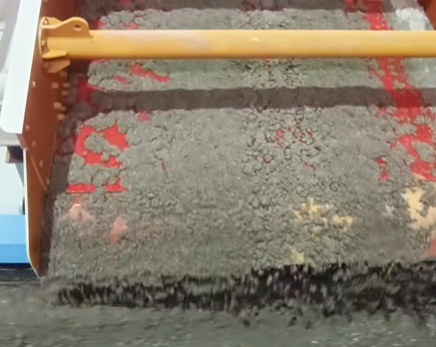

The trommel screen is used to divide the jigging material into coarse material and fine material, which is convenient for the coarse material to be sorted and crushed through the circulating vortex in the next step, and the sorting rate of copper and aluminum is improved.

Crushing:The slag crusher is used to reduce the particle size of the slag step by step, reduce and crush it, so as to improve the metal sorting rate; Blacksmiths are used to break and disperse iron slag mixtures.

Magnetic Separation: the iron slag mixture in the slag is separated for crushing; The iron blocks and iron powder in the slag are separated for recycling.

Eddy Current Sorting: Eddy Current Separator is used to sort and recover the aluminum metal in the slag.

Gravity Sorting: using a jig and shaker to sort and recover copper metal.

Permanent Magnetic Separator:Permanent Magnetic Separator has a permanent magnet that generates a strong magnetic field to attract and trap ferrous contaminants from a variety of materials. It can effectively automatically separate iron from other materials to achieve high purity iron recovery.

Sand Washing: The material is cleaned under the rotation of the impeller to remove the impurities covering the surface of the sand and gravel, and the cleaning machine is completely dehydrated, which can effectively reduce the powder content of the material.

Dewatering: the separated metal is dehydrated by vibrating dewatering screen; The dewatering screen separates water and sand, and the moisture content of the finished material after dehydration is low.

Conclusion

After the product is treated, the resource utilization is realized, and the environmentally friendly sand is directly used as a road paving material, and can also be made into environmentally friendly bricks and cement concrete, which can directly turn waste into treasure; The sorted metal substances can be processed into metal products in metal processing plants.