Up-suction Magnetic Separator Application

The up-suction magnetic separator is mainly used in the separation of iron from various slag material, such as scrap steel, steel slag treatment, and slag sorting, and the sepatated iron particle size can be under 5mm. Garbage sorting can effectively solve the problem of belt damage of belt iron remover. This equipment can still operate reliably in extremely harsh environments.

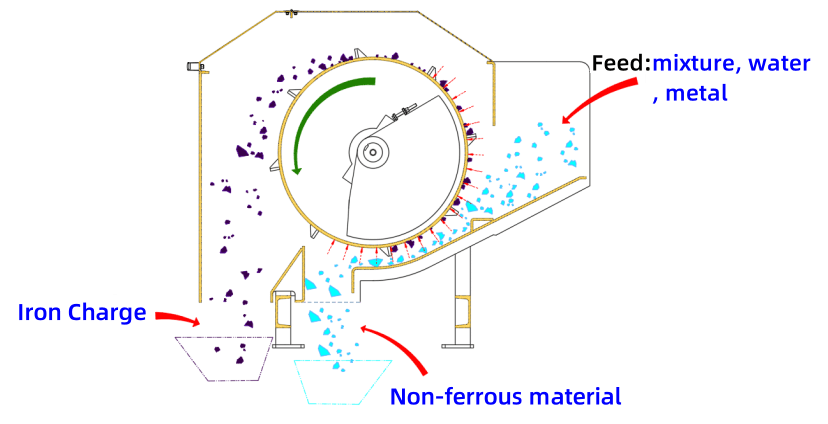

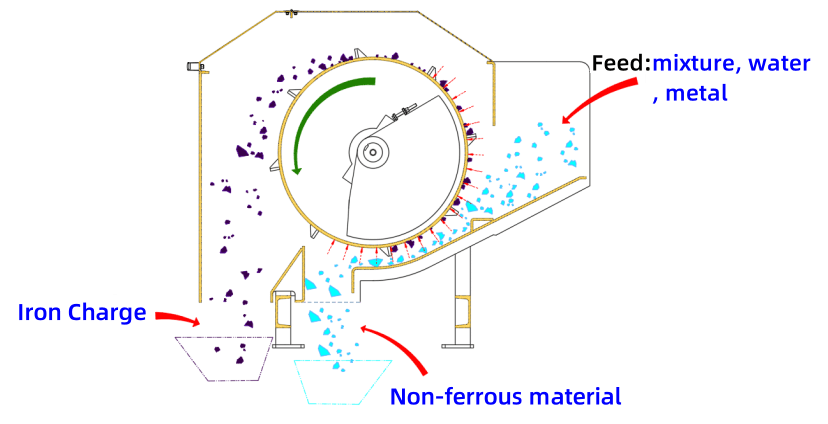

Counterflow Magnetic Separator Principle

As the material enters the operational region of the magnetic drum, the iron particles are attracted and cling to the drum's surface. During the drum's counterflow rotation, the adhered iron particles move to the non-magnetic zone. In this zone, due to the combined effects of gravity and inertial force, the iron particles detach automatically and fall into the discharge port, achieving iron separation. The counterclockwise motion of the drum is intentionally designed to minimize blockages during continuous operation

Counterflow Magnetic Separator Principle Features

●Low demagnetization rate and high sorting purity;

●The upper part of the magnetic shaft adopts ferrite magnetic blocks, with long magnetic lines that are not easy to demagnetize and rust.

●The magnetic zone can be adjusted up and down according to material conditions.

●Stable operation, low failure rate, and long service life.

●The equipment welding and assembly process is rigorous. The magnetic shaft is waterproof.

● Wear-resistant and rust resistant main components, made of stainless steel material

●Compact structure, easy to install and can run stable even in terribly severe enviroment.

●A transparent window on the top is designed for convenient observation.

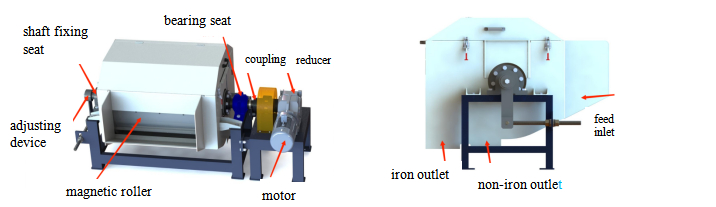

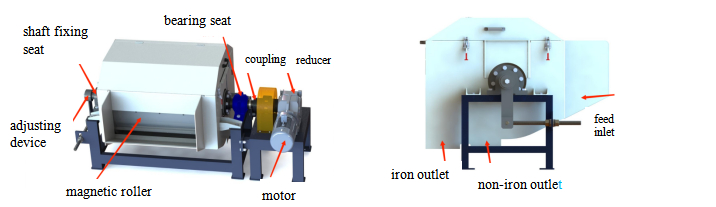

Durable Up-suction Magnetic Separator Structure

Aluminum end caps, stainless steel flanges are wear-resistant, and the groove is made of stainless steel. The magnetic drum is made of 304 stainless steel, which is rust-proof, anti-corrosion and strictly sealed.

RUIJIE Up-suction Magnetic Separator Technical Parameter

Model | Roller Diameter (mm) | Roller Rotation Speed(r/min) | Processing Capacity (t/h) | Power(kw) | Weight (L*W*H) (mm) | Weight(kg) |

SX6090R | 600 | 22 | 25-40 | 3.0 | 2200*1236*1059 | 1130 |

Iron Material Separated By the Up-suction Magnetic Sorting Machine

The countercurrent wet selector magnetic separator is used for automatic and continuous recovery of heavy medium in coal washing plant, and can also be used to recover ferromagnetic ore.

We use rare earth NdFeB magnetic system, which has a higher magnetic force than other similar products. The media recovery rate is 99.9%.

Installation Position in IBA Wet Sorting Production Line