Jig machines have become an integral part of various industries, revolutionizing the process of separating different materials efficiently and effectively. In this article, we will delve into the world of jig machines, exploring their functionalities, applications, advantages, and factors to consider when choosing the right one for your specific needs.

To begin with, we will unravel the workings of a jig machine, understanding the mechanisms that enable it to achieve optimum separation results. How Does a Jig Machine Work? We will provide a comprehensive overview of the step-by-step processes involved, shedding light on the ingenious engineering behind this remarkable device.

Moving on, we will explore the vast array of applications that jig machines cater to. From mineral processing and coal washing to metal recovery and ore beneficiation, these versatile machines have found their place in multiple industries. Applications of Jig Machines will highlight the diverse sectors that benefit from their utilization and how they streamline operations to enhance productivity.

Furthermore, we will discuss the advantages that come with using jig machines. Whether it is their ability to handle a wide range of particle sizes, their cost-effectiveness, or their environmentally friendly nature, Advantages of Using Jig Machines will showcase the numerous benefits that make them the preferred choice in many industrial settings.

Lastly, we will delve into the factors that should be considered when selecting a jig machine. With an abundance of options available in the market, it is crucial to make an informed decision based on specific requirements. Factors to Consider When Choosing a Jig Machine will provide valuable insights to aid in the decision-making process, ensuring the selection of the most suitable machine for optimal results.

In conclusion, this article aims to provide a comprehensive understanding of jig machines, their functionality, applications, advantages, and key considerations when choosing the right one. Whether you are a professional seeking to enhance your industrial processes or simply curious about this innovative technology, this article will serve as a valuable resource in unraveling the mysteries of jig machines.

How Does a Jig Machine Work?

A jig machine is an essential piece of equipment used in various industries, including mining and mineral processing. Its primary function is to separate valuable minerals from waste materials by utilizing the principle of gravity separation. But how exactly does a jig machine work?

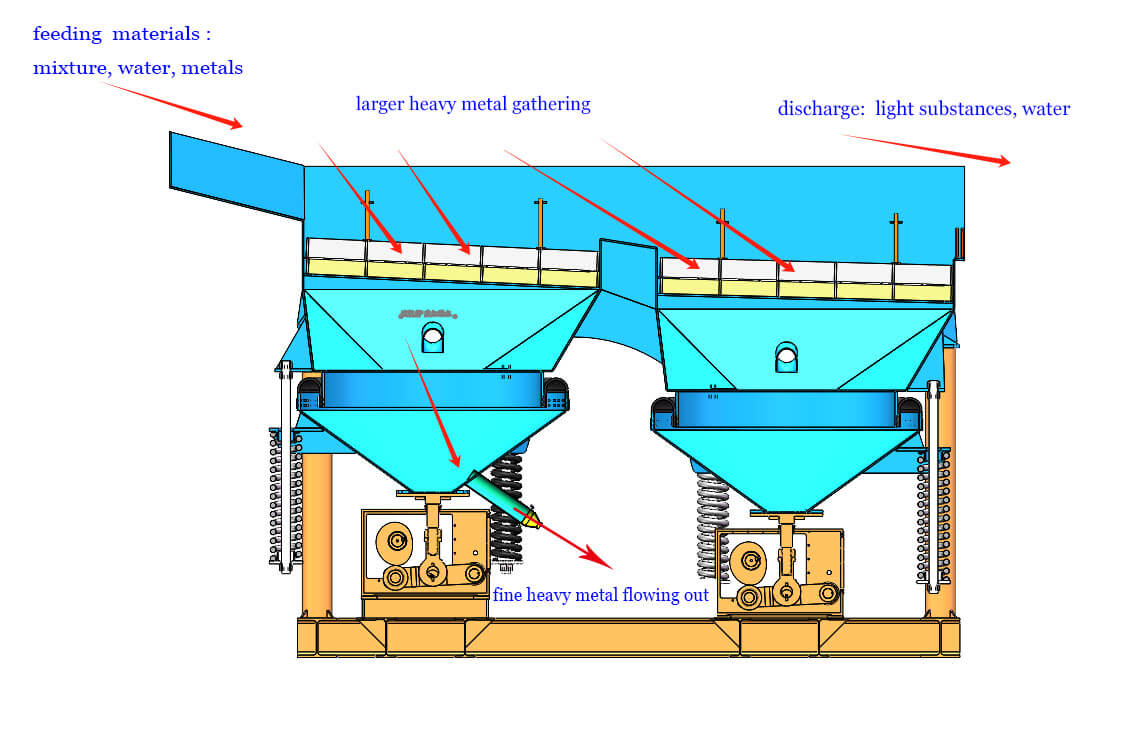

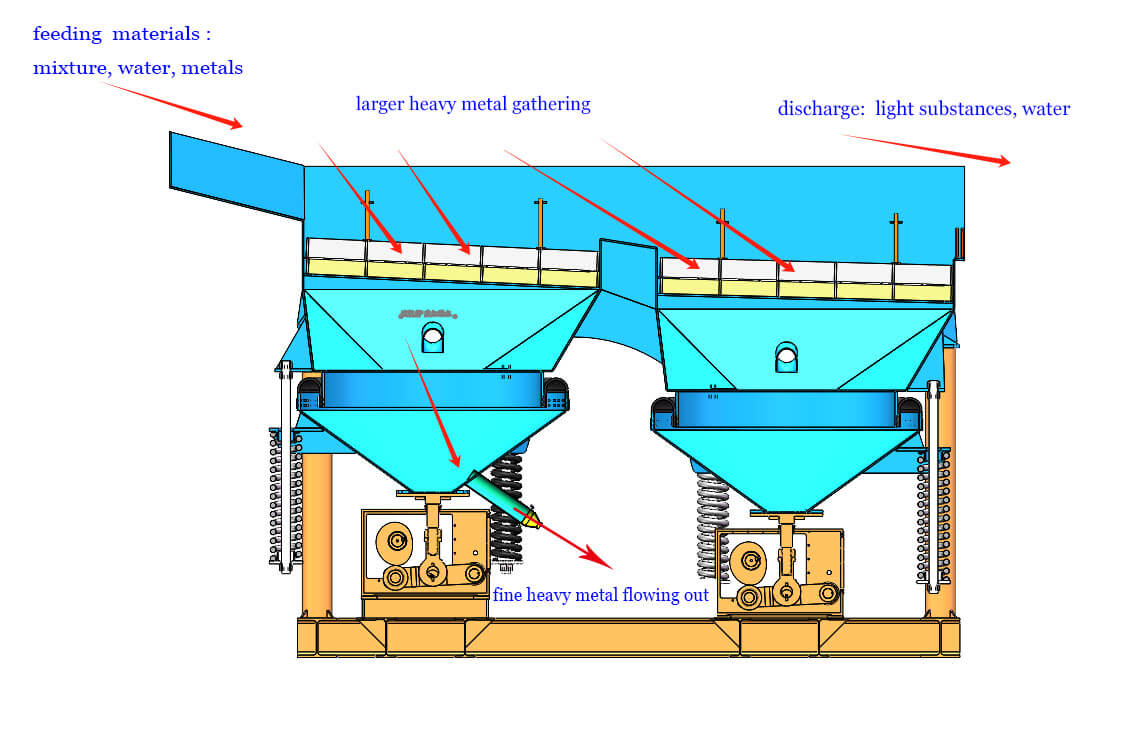

The operation of a jig machine starts with the feeding of raw materials into a specially designed container called a jigging chamber. This chamber is equipped with a screen or sieve to classify the particles based on their size. Large particles are left on the sieve mesh, while small particles fall into the jig chamber from the sieve hole.

Once the materials are classified, the jig machine uses pulsating water flow to create movement within the chamber. This pulsation causes the particles to stratify by density, with the heavier minerals sinking to the bottom and the lighter ones floating to the top. This process is known as stratification.

The next step in the operation of a jig machine is the actual separation of the minerals. The heavier particles, which contain the valuable minerals, are collected at the bottom of the jigging chamber. These particles are then discharged through a valve, while the lighter waste materials are removed from the top.

To achieve optimal separation, the jig machine relies on the differences in specific gravity between the minerals. Specific gravity is a measure of the density of a substance compared to the density of water. By adjusting the pulsation frequency and water flow rate, operators can optimize the separation process for different types of minerals.

One of the key advantages of using a jig machine is its ability to handle a wide range of particle sizes. The jig machine is widely used in the production to separate copper, silver, tin, tungsten, tantalum, niobium, titanium, zirconium, primary ores and placers of chromium.

Applications of Jig Machines

Jig machines, also known as jigging equipment, are versatile tools widely used in various industries for a range of applications. These machines are designed to separate different materials based on their specific gravity, allowing for efficient and precise sorting. The applications of jig machines are diverse and can be found in mining, mineral processing, and recycling operations.

One of the primary uses of jig machines is in the mining industry. They are commonly employed in the extraction of minerals such as tin, and diamonds. Jigging equipment is particularly effective in separating valuable minerals from gangue materials based on their density differences. This process ensures that only the desired minerals are collected, increasing the overall efficiency of the mining operation.

In addition to mining, jig machines are extensively used in mineral processing plants. These machines play a crucial role in the concentration of valuable minerals from ore. By utilizing the principle of gravity separation, jigging equipment can effectively separate minerals of different densities. This enables the production of high-grade concentrates, which can be further processed or sold directly to customers.

Jig machines also find applications in the recycling industry. They are utilized in the separation and recovery of materials from waste streams. By employing jigs, recyclable materials such as plastics, metals, and glass can be sorted based on their specific gravity. This allows for the efficient recovery of valuable resources, minimizing waste and promoting sustainability.

Furthermore, jig machines have proven to be useful in the field of coal preparation. In coal washing plants, jigging equipment is utilized to separate coal from impurities, such as rock and shale. The jigging process ensures the production of clean coal, which can be used for power generation and other industrial purposes. Additionally, the use of jig machines in coal preparation helps to reduce the environmental impact of coal mining and combustion.

Advantages of Using Jig Machines

Jig machines have become an essential tool in various industries due to their numerous advantages. These machines are widely used in mining, mineral processing, and ore beneficiation processes. With their efficient operation and reliable performance, jig machines offer significant benefits to businesses and individuals alike.

One of the primary advantages of using jig machines is their ability to separate different materials based on their specific gravity. This process, known as gravity separation, allows for the effective separation of heavy and light particles. By utilizing the principle of gravity, jig machines can effectively separate valuable minerals from gangue materials, resulting in higher purity and increased productivity.

Another advantage of jig machines is their versatility. These machines can handle a wide range of materials, including coal, iron ore, tin, and tungsten. They can be easily adjusted to accommodate different feed sizes and densities, making them suitable for various applications. Whether it is for roughing, cleaning, or scavenging purposes, jig machines can effectively recover valuable minerals and maximize the overall efficiency of the process.

In addition to their versatility, jig machines offer a cost-effective solution for mineral processing operations. These machines have low power consumption and require minimal maintenance, reducing operational costs in the long run. Furthermore, the high recovery rates achieved by jig machines contribute to increased profitability, as valuable minerals are effectively recovered and utilized.

Jig machines also boast a compact design, making them suitable for both small-scale and large-scale operations. Their small footprint allows for easy installation and integration into existing processing plants. Additionally, jig machines are known for their ease of operation, requiring minimal training and supervision. This user-friendly nature ensures that businesses can quickly adopt and utilize jig machines to enhance their overall productivity.

Factors to Consider When Choosing a Jig Machine

When it comes to choosing a jig machine, there are several factors that need to be considered. A jig machine is a vital tool in various industries such as mining, construction, and woodworking. It is used to separate and concentrate different materials based on their specific gravity. With so many options available in the market, it can be overwhelming to select the right jig machine for your needs. In this article, we will discuss some important factors that should be taken into account when making this decision.

First and foremost, it is crucial to assess the capacity and size of the jig machine. The capacity refers to the amount of material that the machine can handle at a given time. This is an important consideration as it determines the efficiency and productivity of the machine. Additionally, the size of the jig machine should be compatible with the available space in your workplace. It is essential to measure the dimensions accurately to ensure a proper fit.

The quality and durability of the jig machine are also critical factors to consider. Investing in a high-quality machine is essential for long-term use and efficient operation. The machine should be made from sturdy materials that can withstand the rigors of heavy-duty work. Additionally, it is advisable to choose a machine from a reputable manufacturer that offers warranties and after-sales support. This provides assurance and peace of mind in case any issues arise in the future.

Furthermore, the ease of use and maintenance should not be overlooked. A user-friendly jig machine with clear instructions and intuitive controls can save time and effort during operation. Additionally, regular maintenance is crucial to ensure the longevity of the machine. It is important to choose a machine that is easy to clean, service, and repair to minimize downtime and maximize productivity.

Conclusion

Jig machines are essential tools for mineral processing operations as they can separate valuable minerals from waste materials through gravity separation. They are versatile and find applications in various industries such as mining, mineral processing, recycling, and coal preparation. Jig machines offer efficient and effective separation solutions by utilizing specific gravity. Their use improves operational efficiency, promotes sustainable practices, and contributes to environmental sustainability.

These machines provide significant benefits, including cost-effectiveness and reliability, making them crucial for optimizing resource utilization and achieving success in respective industries. However, selecting the right jig machine requires careful consideration of factors like capacity, size, material type, quality, and ease of use. Investing in a reliable and efficient jig machine can enhance productivity and contribute to the success of operations.