Application

Eddy current separator is one of the newly specialized machines in the areas of recycling solid wastes. This development aims at better metal recovery from solid wastes and discovering as many potential metal resources as possible in domestic and industrial wastes.

Principle

A conveyor belt transports the material to the vibrating feeder. The high-frequency vibration of the vibrating feeder screens out moisture from the material and creates a forward thrust that propels the material evenly into the eddy current separator. When the eddy current separator is in operation, a strong magnetic field of high frequency is developed on the surface of the sorting drum because of the rapid rotation of the magnetic drum; once the non-ferrous metal passes through this magnetic field, an eddy current will be generated within it, and this eddy current will in turn generate a magnetic field in the opposite direction to that of the original magnetic field, causing non-ferrous metals (copper, aluminum, etc.) to be propelled forward along their transport path by a repulsive magnetic field, thus separating them from other non-metallic substances and achieving the purpose of sorting.

Feature

●Good design: simple to set up, easy to use, and quick to conservation.

●Skirt style feeding belt: This, with small dust strips, helps keep things clean and stops materials from dropping onto the feeding belt. Thus, it saves the belt surface and vortex rotor from wear.

●Runs well for long times: Few problems and lasts a long while.

●Equiped with well-known brand motor: works more stable and prolong service life.

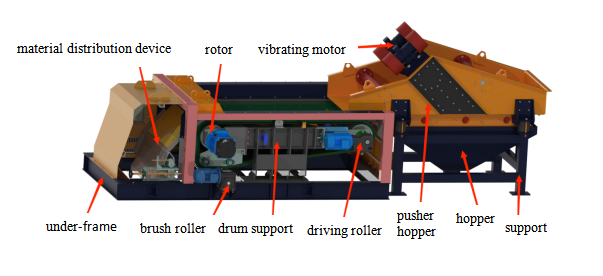

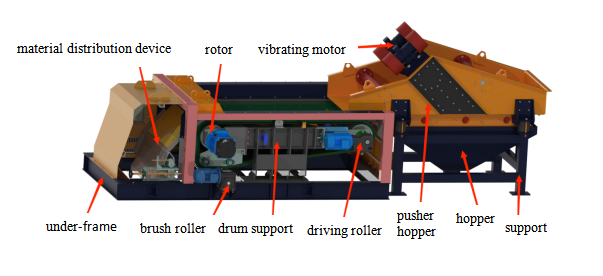

Structure

Technical Parameter

Model | Dimensions (L*W*H) (mm) | Effective Belt Width(mm)

| Feeder Specification(mm) | Processing Capacity(t/h) |

RJ065AL-R | 3311x1778x1222 | 650 | 1535x887x1278 | 2~8mm,2t/h 8~30mm,4t/h 30~80mm,5t/h |

RJ080AL-R | 3311x1778x1222 | 800 | 1535x1091x1278 | 2~8mm,2.5t/h 8~30mm,5.5t/h 30~80mm,7t/h |

RJ100AL-R | 3311x2008x1222 | 1000 | 2440x1356x1897 | 2~8mm,3.5t/h 8~30mm,6.8t/h 30~80mm,10t/h |

RJ100AL-R2 | 3843x2008x2529 | 1000 | 2440x1356x2927 | 2~8mm,3.5t/h 8~30mm,6.8t/h 30~80mm,10t/h |

RJ150AL-R | 3311x2686x1222 | 1500 | 2440x1815x1925 | 2~8mm,6t/h 8~30mm,12t/h 30~80mm,15t/h |

RJ150AL-R2 | 3843x2686x2529 | 1500 | 2440x1815x2955 | 2~8mm,6t/h 8~30mm,12t/h 30~80mm,15t/h |

RJ200AL-R2 | 3843x3241x2529 | 2000 | 2440x2369x2955 | 2~8mm,7.5t/h

8~30mm,15t/h

30~80mm,18t/h |

Advantages

The industrial eddy current separator is a automatic sorter machine , highly applicable and widely used in Incinerator Bottom Ash IBA recovery, aluminium can recycling, and other non-ferrous metal material separation.

It is equiped a cabnet system for antomatic control of the magnetic separarors, and matched a dewatering screen for actual use.

Ruijie user-friendly innovative eddy current separator has a high recovery rate up to 98% and large process capacity. If choose a belt with 65cm effective width, it can process 4 tons raw materials( 8~30mm) per hour.

Ruijie offer different models for selection, also support tailor-made non-ferrous metal processing machine.