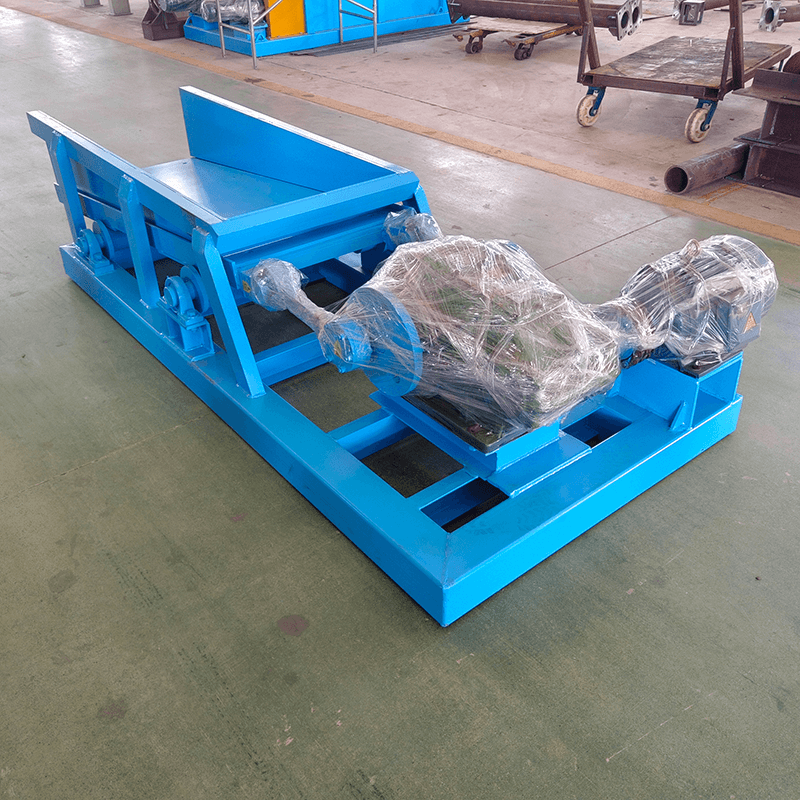

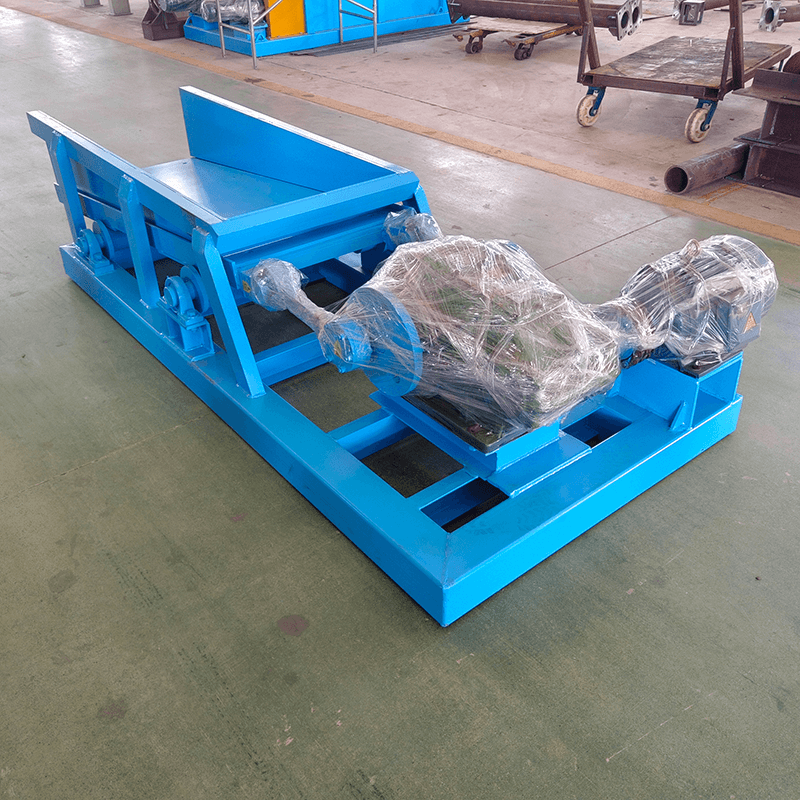

Reciprocating feeders are vital for efficient material transportation in various industries. They operate through a back-and-forth motion, driven by an electric motor. With robust construction and precise control over the feed rate, reciprocating feeders handle a wide range of materials.

They are suitable for mining, quarrying, power plants, cement plants and construction sites, ensuring a seamless flow of materials.

A reciprocating feeder is a crucial component in many industries, helping to efficiently transport bulk materials from one place to another. This mechanical device operates on a simple yet effective principle, ensuring a steady flow of materials without any blockages or disruptions.

The working mechanism of a reciprocating feeder involves a tray or a conveyor belt that moves back and forth in a reciprocating motion. This motion is usually driven by an electric motor or a hydraulic system, which provides the necessary power and control.

At the start of the process, the bulk material is loaded onto the feeder tray. As the tray moves forward, the material is pushed along with it. This forward motion creates a continuous flow of material, ensuring a consistent supply to downstream processes.

Once the tray reaches its furthest point, it starts moving back in the opposite direction. This backward motion allows the tray to return to its original position, ready for another cycle. As the tray moves backward, any excess material that may have accumulated on the tray is pushed off, preventing any overloading or spillage.

The reciprocating motion of the feeder tray is carefully timed and controlled to ensure optimal performance. The speed and frequency of the reciprocating motion can be adjusted based on the specific requirements of the application. This flexibility allows the feeder to handle different types of materials and varying feed rates.

One of the key advantages of a reciprocating feeder is its ability to handle a wide range of materials, including both fine and coarse particles. The design of the feeder tray can be customized to accommodate different material sizes and properties, ensuring efficient handling and minimal material degradation.

In addition to its versatility, a reciprocating feeder also offers excellent reliability and durability. The robust construction and high-quality components ensure long-lasting performance even in demanding industrial environments. Regular maintenance and inspections are essential to keep the feeder running smoothly and prevent any potential issues.

Advantages and Applications of Reciprocating Feeders

Reciprocating feeders are widely recognized for their numerous advantages and versatile applications in various industries. These efficient machines are designed to feed bulk materials consistently and reliably, making them an essential component in many production processes.

One of the key advantages of reciprocating feeders is their ability to handle a wide range of materials. Whether it is coal, ore, sand, or even bulk solids with varying sizes and shapes, these feeders can effectively handle them all. This adaptability makes them suitable for diverse industries such as mining, construction, cement, and power generation.

Another advantage of reciprocating feeders is their precise and controlled feed rate. These feeders are equipped with adjustable stroke lengths and speeds, allowing operators to regulate the material flow according to specific requirements. This precise control ensures optimal feeding, preventing overloading or underfeeding of downstream equipment. As a result, the overall efficiency and productivity of the production process are significantly enhanced.

Reciprocating feeders are also known for their robust construction and durability. These machines are designed to withstand heavy-duty operations and harsh environments, ensuring long-term reliability and minimal maintenance. With the right maintenance and care, reciprocating feeders can deliver consistent performance for years, making them a cost-effective investment for businesses.

The applications of reciprocating feeders are diverse and extensive. In the mining industry, these feeders are commonly used to transport ore from storage bins to crushers or conveyors. They play a crucial role in maintaining a steady flow of material, preventing disruptions in the production process. In the construction industry, reciprocating feeders are utilized to transport aggregates and other bulk materials to the desired location, facilitating the smooth execution of construction projects.

Reciprocating feeders also find applications in the cement industry, where they are used to transport limestone, shale, and other raw materials to the crushing and grinding mills. By ensuring a consistent supply of materials, these feeders contribute to the efficient operation of the cement manufacturing process.

Conclusion

Reciprocating feeders have a crucial role in various industries as they facilitate the smooth and efficient transportation of bulk materials. These feeders have a simple yet effective working mechanism and are versatile and reliable, making them indispensable for many applications.

They can handle both fine powders and coarse aggregates and ensure a consistent and controlled flow of materials, contributing to overall productivity and success. Reciprocating feeders offer numerous advantages and have diverse applications in industries such as mining, construction, and cement production.

They can handle a wide range of materials, provide precise feed rate control, and have robust construction and durability. These feeders play a crucial role in enhancing productivity and ensuring smooth operations in various industries.